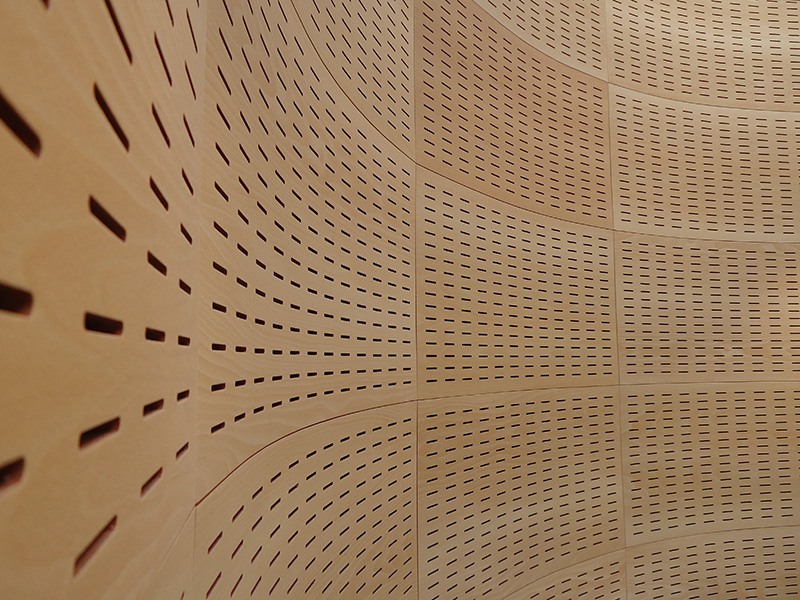

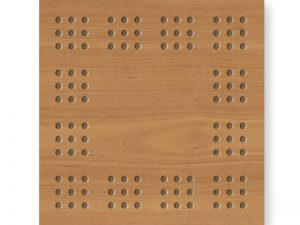

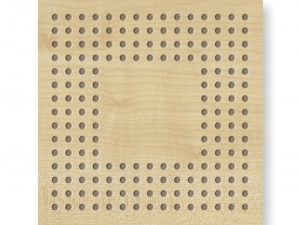

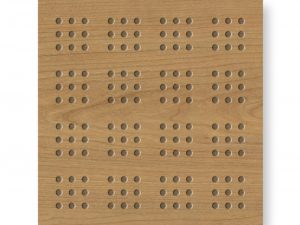

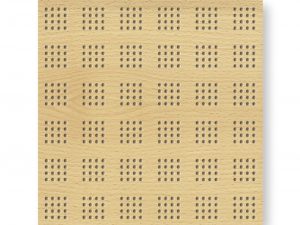

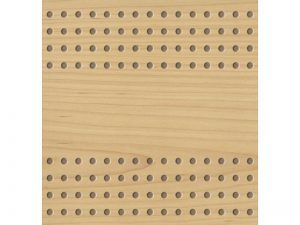

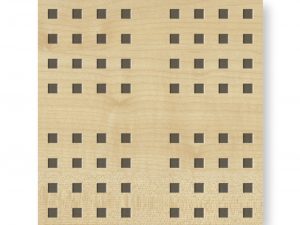

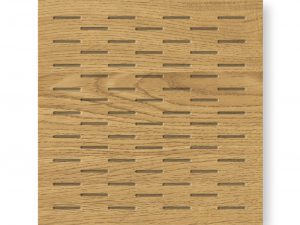

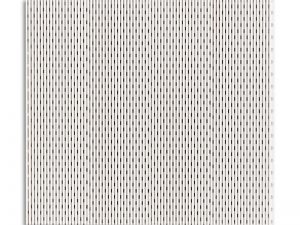

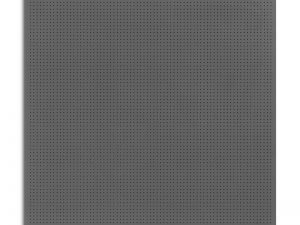

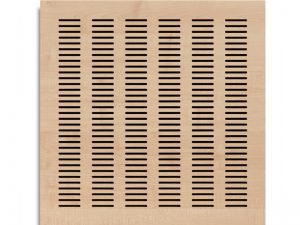

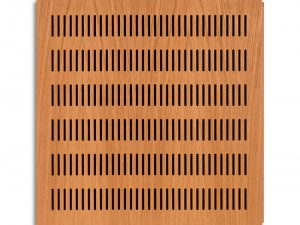

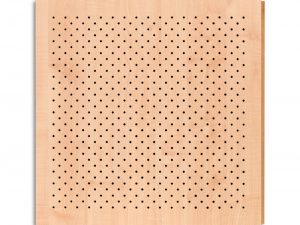

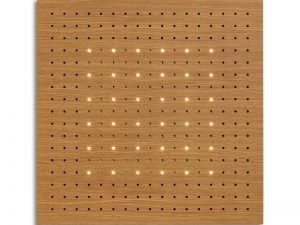

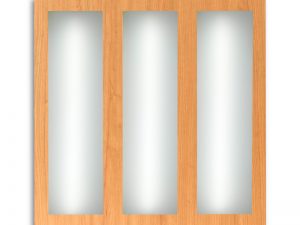

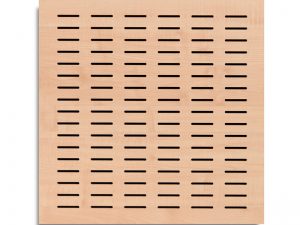

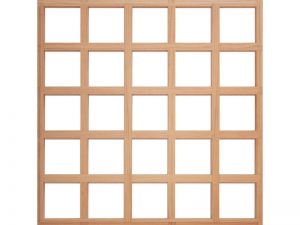

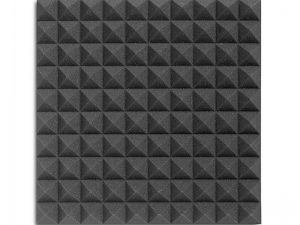

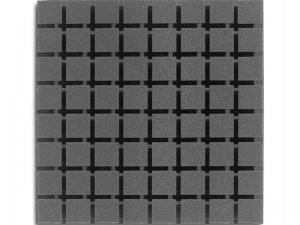

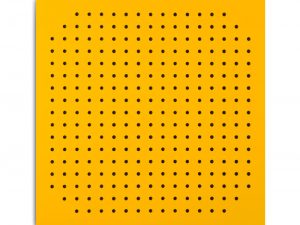

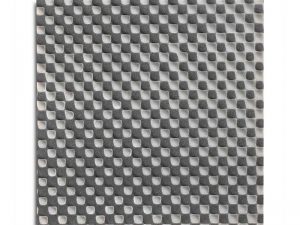

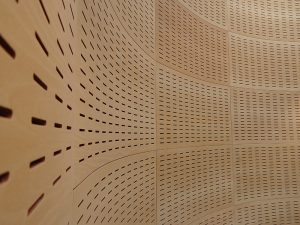

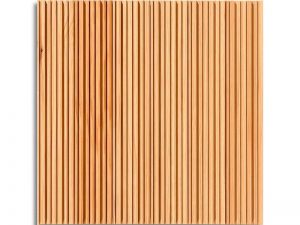

Acoustic panels play a fundamental role in controlling sound quality within interior spaces. At Finixia, our acoustic wood panels are designed to reduce noise, improve sound clarity and create more comfortable environments in projects where acoustics are essential, such as hotels, offices, auditoriums or public buildings.

By combining sound-absorbing materials with carefully engineered wooden surfaces, these panels help minimise reverberation and manage sound waves effectively. Their design allows sound to penetrate the panel and be dissipated within the structure, improving acoustic performance without compromising aesthetics.

Used on walls and ceilings, Finixia acoustic panels offer an effective balance between technical performance and architectural integration, making them a reliable solution for interior acoustic conditioning.