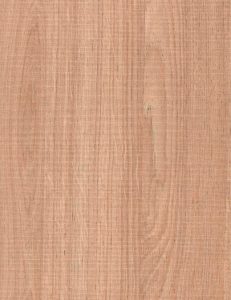

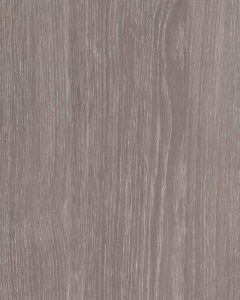

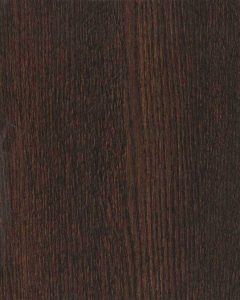

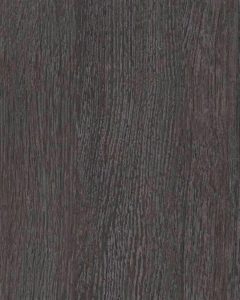

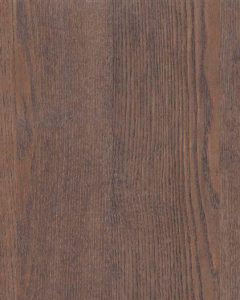

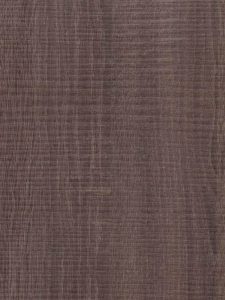

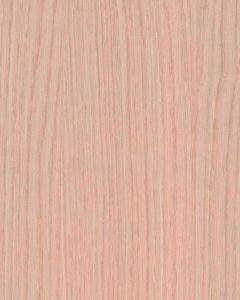

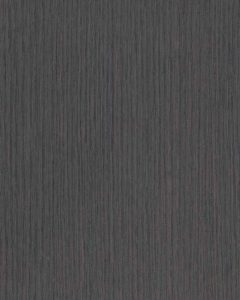

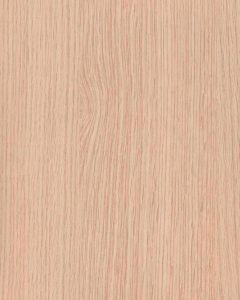

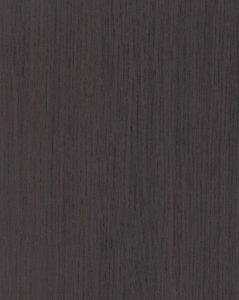

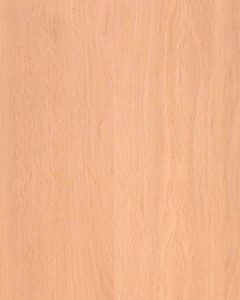

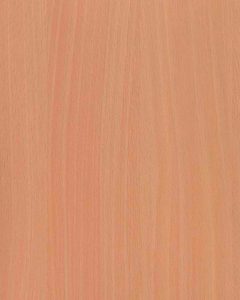

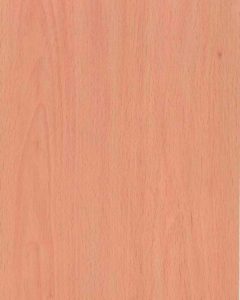

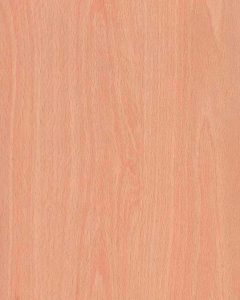

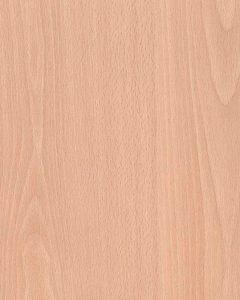

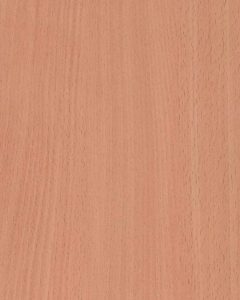

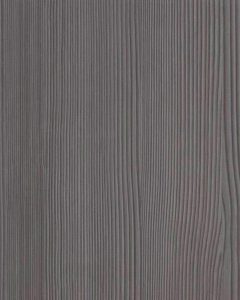

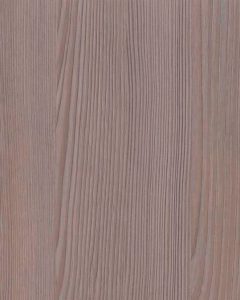

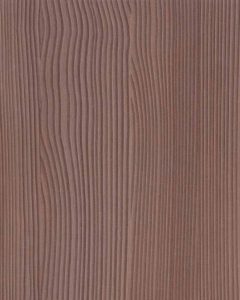

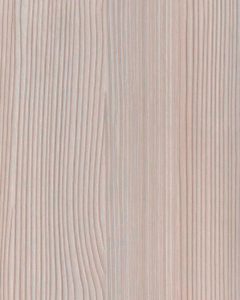

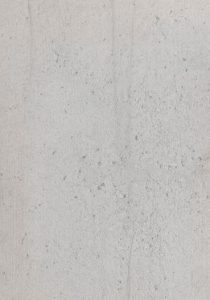

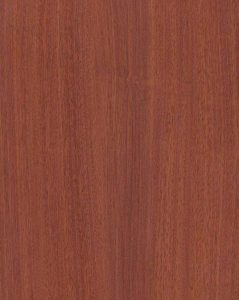

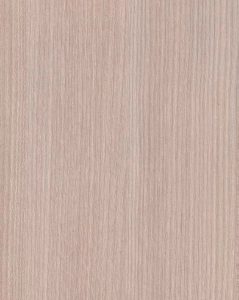

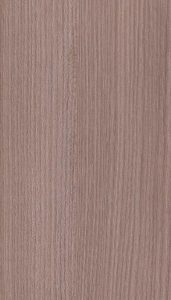

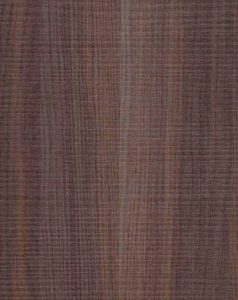

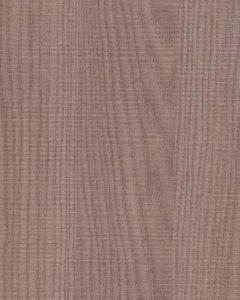

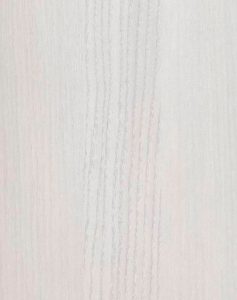

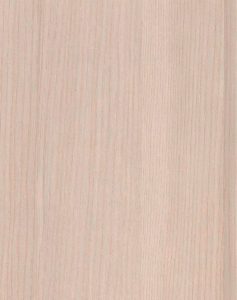

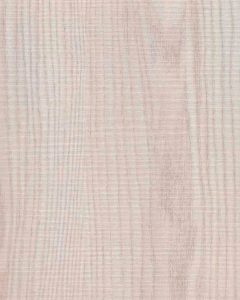

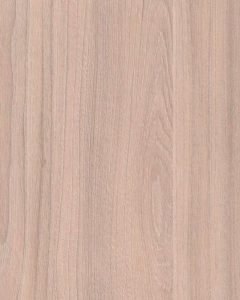

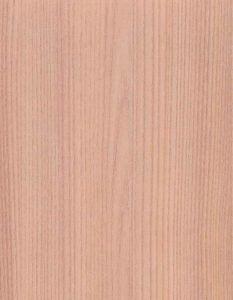

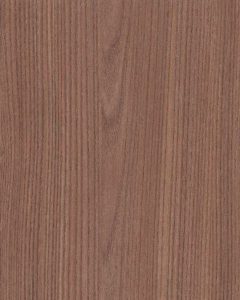

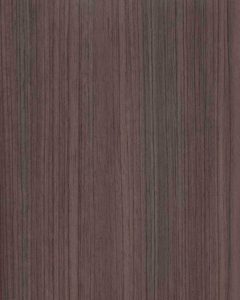

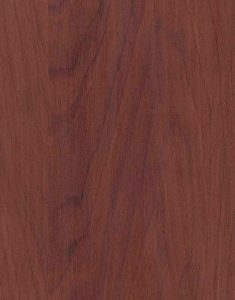

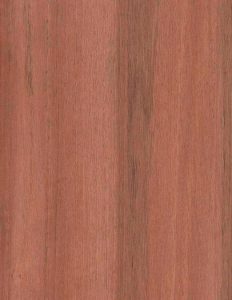

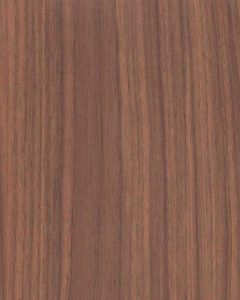

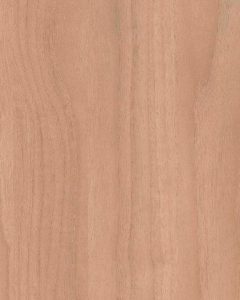

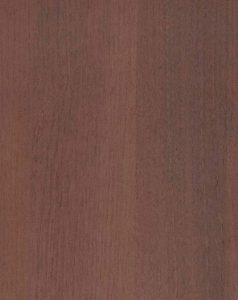

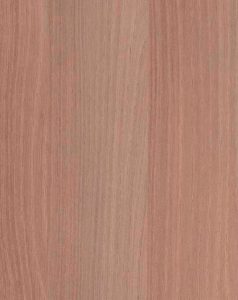

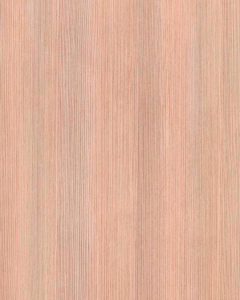

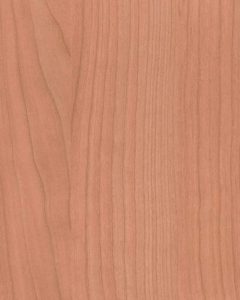

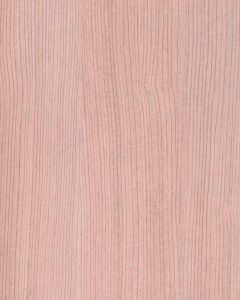

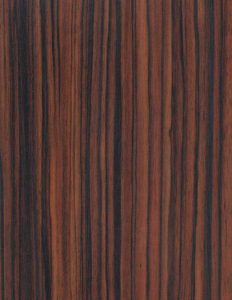

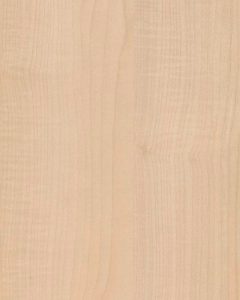

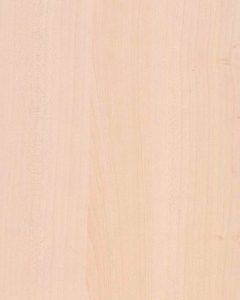

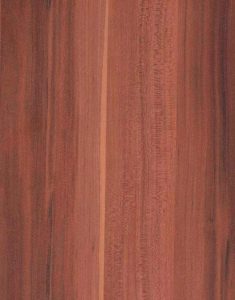

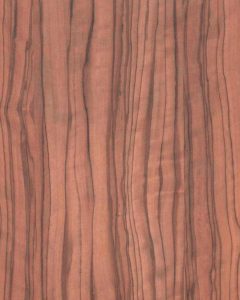

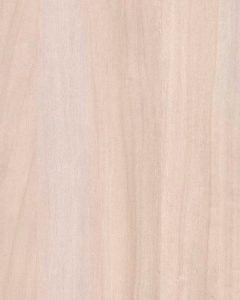

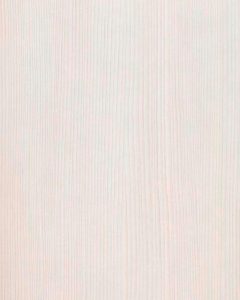

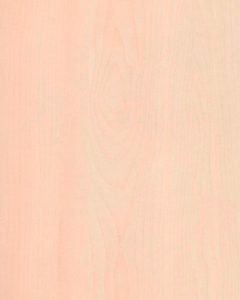

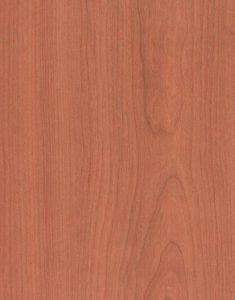

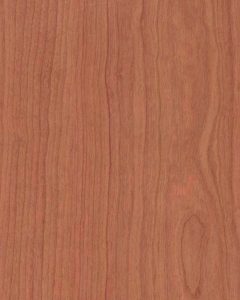

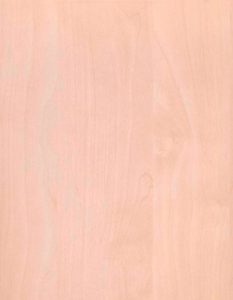

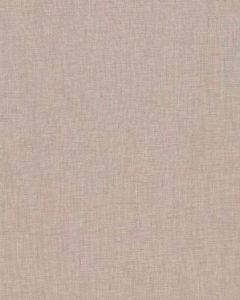

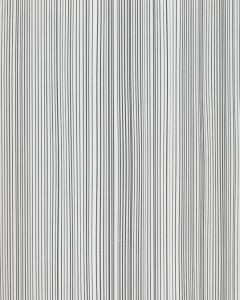

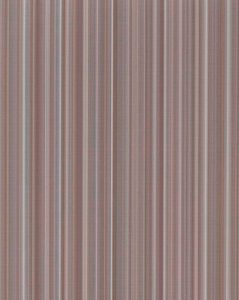

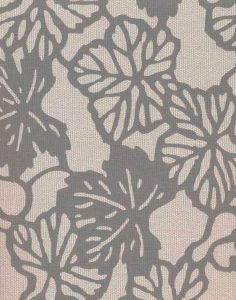

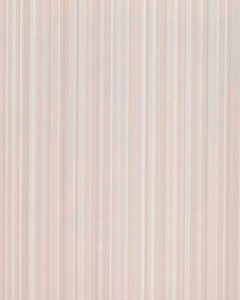

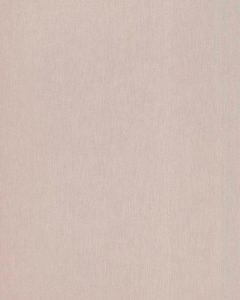

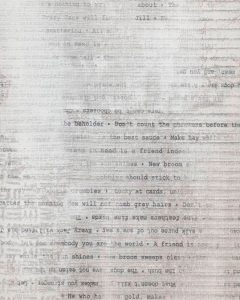

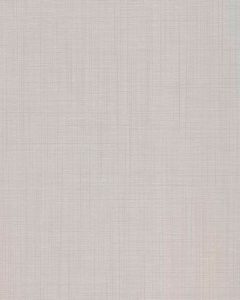

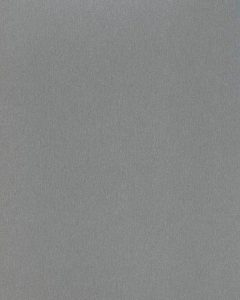

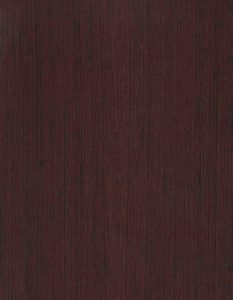

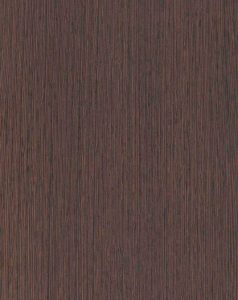

Continuous Pressure Laminate (CPL) is a versatile laminate solution designed for projects where flexibility, thin thickness and efficient application are key. At Finixia, CPL is supplied as an ideal surface material for furniture, doors and interior elements that require postforming or curved finishes.

Thanks to its continuous production process, CPL allows greater freedom in design and format, making it especially suitable for large-scale manufacturing and customised applications. Its adaptability to curved surfaces and its ease of handling make CPL a practical and cost-effective option for industrial and contract projects.

Available in sheets or rolls, Finixia CPL laminates offer consistency in quality and finish, supporting efficient production while maintaining a refined decorative appearance.