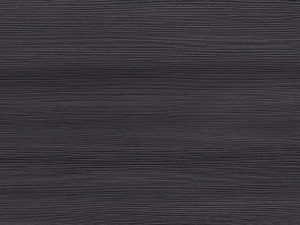

1. WOOD VENEER FACED PANELS Wood veneer faced board, is an option for high quality finishing. The unique quality of this product begins with the real wood veneers, which come from an immense variety of natural wood trees types. They are carefully selected and accurately jointed, recreating natural wood in panels of beautiful patterns and suitable dimensions. Wood particleboard, MDF or plywood are chosen as the most suitable cores for this fine product, due to their workability and versatility, either in standard grade or with special characteristics.

Controlled pressing and finishing techniques complement the superior quality of the raw materials. Wood veneer panels are available in a variety of veneer cuts such as: Quarter cut, Crown cut, Rotary cut and Burrs. | | Properties: - Stability

- Uniform grain and wood beauty

- Alternative to solid wood

- Environmentally friendly

|

| | | |

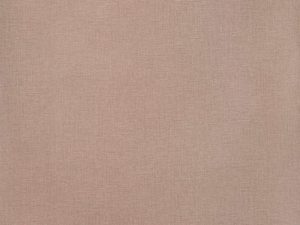

2. LACQUERED PANELS Lacquer, a bright material available in many colors, consists of a fiberboard panel coated with polyester and polyurethane paints. The lacquer finish can be matt, gloss or metallic, and covers the entire surface. Lacquer is more delicate than laminate and other synthetic surface finishes and may be subject to changes in color. For this reason, its quality is determined by the type of paint used. To guarantee long-lasting color, use paints with excellent resistance to light. Lacquered consists of raw MDF or HDF covered with water-diluted and UV resistant lacquers. Its most common application is for interior panels and furniture. They are easy to clean and resistant to chemical substances and mechanical impact. | | Properties: - Infinite RAL or Pantone color options

- Alternative to wood finishes

- Uniform colors

|

| | | |

3. ULTRA HIGH GLOSS PANELS Used in projects requiring sophisticated surfaces, with higher brightness, ultra-high gloss panels are composed of MDF (Medium density fiberboard) treated in a variety industrial processes to obtain a decorative panel with a remarkably high gloss finish. Ultra-high gloss panel surfaces boast excellent physical and mechanical performance, added to a resistant surface. Ultra-High Gloss panels are composed with MDF coated with decorative and lacquered paper with UV treatment on his face. The front side covered with edge banding, a layer of polyurethane and transparent primer and one more layer of transparent polyester finishing (solvent base) drying by UV radiation. The back side covered with melamine paper. | | Properties: - High scratch resistance

- Stain resistance

- High gloss

- Easy cleaning

- Long durability

- Antibacterial treatment

- Color stability

- Environmentally friendly

|

| | | |

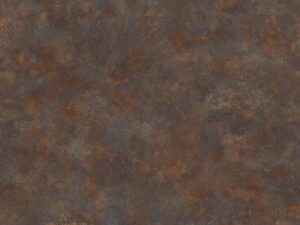

4. LAMINATE FACED PANELS Laminate is one of the most durable decorative surfaces. There are multiple grades of HPL that include chemical resistant, wear resistant for high demand applications, and even fire rated laminates. Finishes as shiny silver, mirror, brushed, and patterned metallic laminates. Laminate is the perfect material for high traffic areas or where a hard-wearing surface is required. The decors are available in a variety of textures and effects, including unicolor, wood grains and materials, with textures including: soft, matt, anti-fingerprint, wood grain and many more special finishes. Laminated panels are available in standard and post-forming quality. | | Properties: - Moisture resistant

- Durability

- Impact and scratch resistant

- Chemical products resistant

- Suitable for contact with food

- Big variety of designs in unicolor, wooden, metallic and stone designs

- Easy to clean

|

| | | |

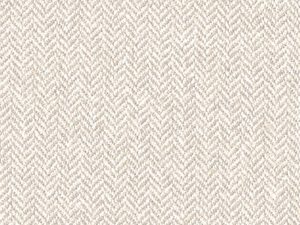

5. MELAMINE FACED PANELS Melamine faced panels are created by high pressure heat bonding impregnated paper to particleboard or MDF to provide a highly wear and water resistant product surface finish. These panels offer a very flexible solution as regards color, pattern and size for furniture and interior decoration, coupled with high resistance to chemical and mechanical agents. Particleboard and MDF are upgraded by surfacing with melamine impregnated decorative paper. The choice of colours, patterns, textures and gloss levels is almost unlimited. Its textures include: soft, matt, pore register (imitating exact wood pore and grain), leather, deep pore, vertical wood grain and horizontal woodgrain. The range is widened still further when combined with different size and core type possibilities. | | Properties: - Economic decorative panel ready-to-use

- Aesthetic designs

- Easy to maintain and to clean

- Surface completely closed pores

- High durability and resistance

- High stability

- Postforming

- Big variety of designs

- Possibility decorative on one or both sides

- Antibacterial

|

| | | |

6. COLOURED MDF PANELS Is a medium-density wood fiberboard that is colored throughout its thickness by a water-based pigment that is resistant to cleaning, sunlight and evaporation. The board has a density of 760 Kg/m², and thanks to the fine structure of its fibers and its homogeneity and compactness, it is easy to handle, and can be cut, drilled, stamped, edge-finished, screw-fastened, glued, etc. Its strong, smooth surface can be sanded, sealed or polished, as well as finished with wax, paint, varnish or lacquer. | | Properties: - Full color inside

- no need to finishing material

- Robust

- Light fast

- Easy to work

- Available in moisture resistant

- Infinite applications

- formaldehyde-free

|